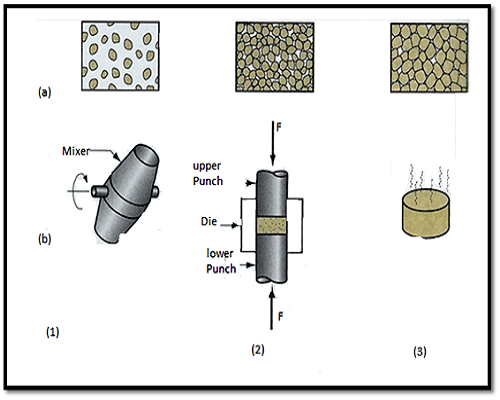

Powder technology is a very important facet of modern manufacture techniques. Powders used in the fabrication process are materials of controlled morphology and size with a diameter ranging between the micron and the millimeter. Nano powders have now been developed for high performance powder technology applications and the preparation of hard metals. Nanopowders will find applications in many areas and several products are already on the market. Powder technology is one of the most extensively employed techniques for the manufacturing of Metal Matrix Composites (MMCs) and Ceramic Matrix Composites (CMCs) because it is a simple and economically efficient method with a large productivity, which permits the use of standard processes that includes, mixing of powders, compaction and sintering under controlled atmosphere.

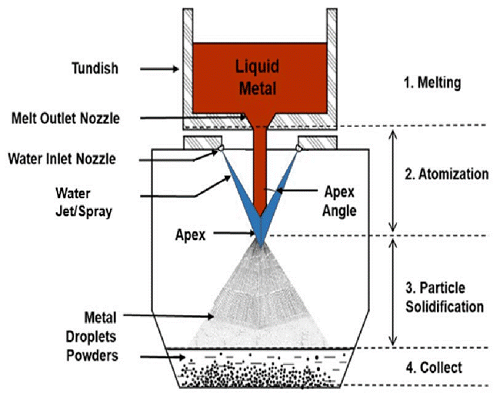

Manufacturing of spare parts with traditional & sophisticated shapes from metal & material powders that cannot be fabricated by another technology is the main target for powder technology department. Applications of the research work in the fabrication process & improvement of the mechanical & physical properties of the manufactured spare parts. Recycling of the different metal scraps into a fine powder by water atomization technique and using these powders in the fabrication of new generations of engineering parts suitable for industrial applications. Recycling of tungsten carbide products by a chemical method converting it to a fine powder that can be used with the fresh one to fabricate cutting tools, carbide tips, breaking bits for mining and traditional ransom cloves with high mechanical properties.

Training

Publication

Projects

Visitor

Powder Technology Department

Powder Technology Department

Powder Technology Department

Powder Technology Department

Powder Technology Department

Powder Technology Department

Powder Technology Department

Powder Technology Department

Powder Technology Department

Powder Technology Department

Powder Technology Department

Powder Technology Department

Powder Technology Department

Membership

PTD