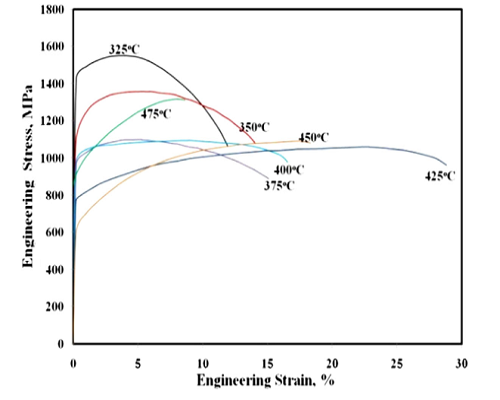

Engineering stress-strain curves of the TBF steel austempered at different temperatures

Attractive properties of TRIP-type bainitic ferrite (TBF) steel ascribe to its unique microstructure of lath structure bainitic ferrite matrix and inter-lath retained austenite films. This work is concerned with obtaining ultrahigh-strength hot forged TBF steel with high elongation and excellent strength-elongation balance. The effect of austempering temperature on the microstructure along with its retained austenite characteristics and tensile properties of a hot forged TBF steel was studied. A detailed investigation correlating the steel structure and its tensile properties was carried out. Tensile strength ranging from 1058 to 1552 MPa was achieved when the hot forged steel was austempered at (325 - 475 °C). Ultra-high tensile strength of 1058 MPa, large total elongation of 29% and excellent strength-elongation balance of 30 GPa % were attained when the steel was austempered at 425 °C. The large total elongation of this steel is mainly due to the uniform fine lath structure matrix and the pronounced TRIP effect of a large amount of retained austenite films which prevents a rapid decrease of strain hardening rate at low strain and leads to a relatively high strain hardening at high strain level. Rapid transformation of blocky retained austenite at low strain in the hot forged TBF steel austempered at higher temperatures results in a rapid increase of initial strain hardening. In addition, the coarse microstructure that contains large blocks of retained austenite / martensite and the insufficient numbers of bainitic ferrite lathes and retained austenite films deteriorate the total elongation and the strength-elongation balance of the TBF austempered at 475 °C.

Read More